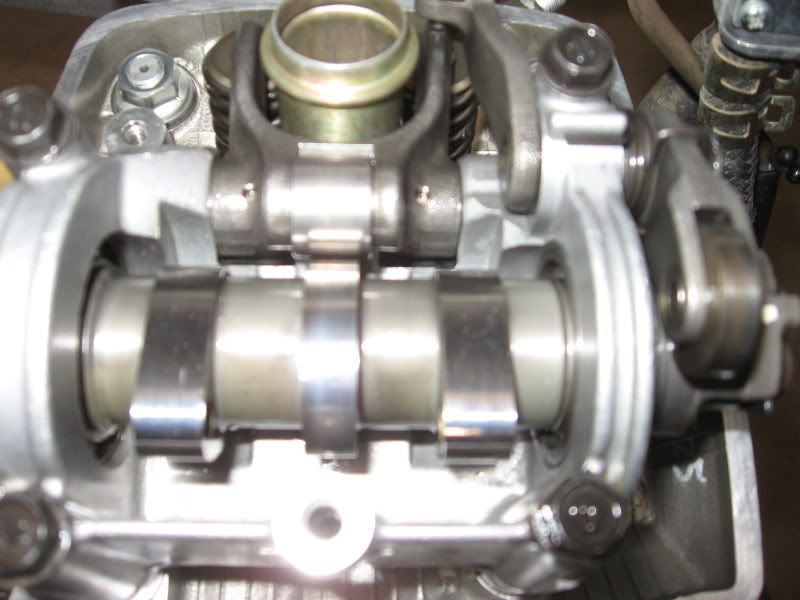

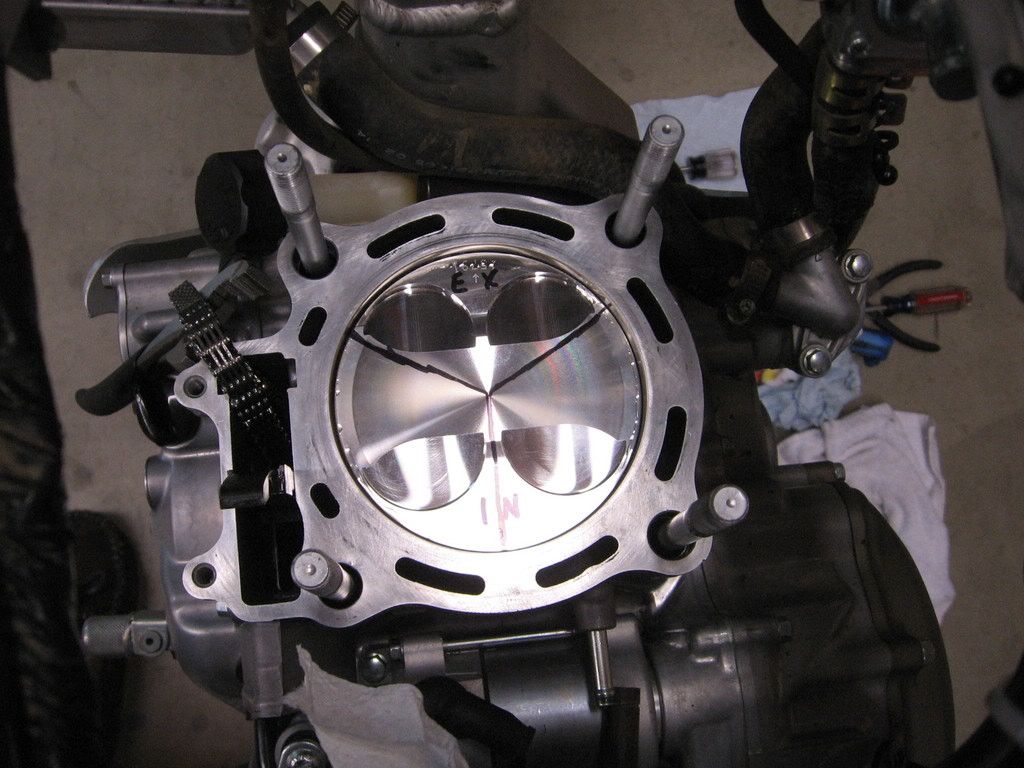

Mark the cylinder in/ex sides for easy reference to orientation.

Mark the piston in/ex. Always use the larger valve recesses as intake.

Here we gonna check ring end gaps. The compression and the 2 oil rings only.

Push the ring down midway with the piston, thats where you wanna check the ring end gap.

Top/Comp Ring target gap is .012in. and the Oil Rings end gap target is .028in., per Honda/Clymer.

I had to take material off the 2 oil rings,(like .004) so I use the flat side of a cutoff blade on my rotary tool. The compression ring end gap was right on, no grind.

Only grind/file one end, square I might add. Here I clean the end(s) with a fine stone.

Ring orientation planned. Install one circlip on the left side of piston, gap facing down.

Ready to shove it !!

Here is the part where you decide dry shove, or wet shove. I do the wet shove.

After insertion, physically move the piston up and down and back and forth. You will feel great resistance up and down. Side to side play should be very noticeable. I demonstrate here with a feeler of .020in.

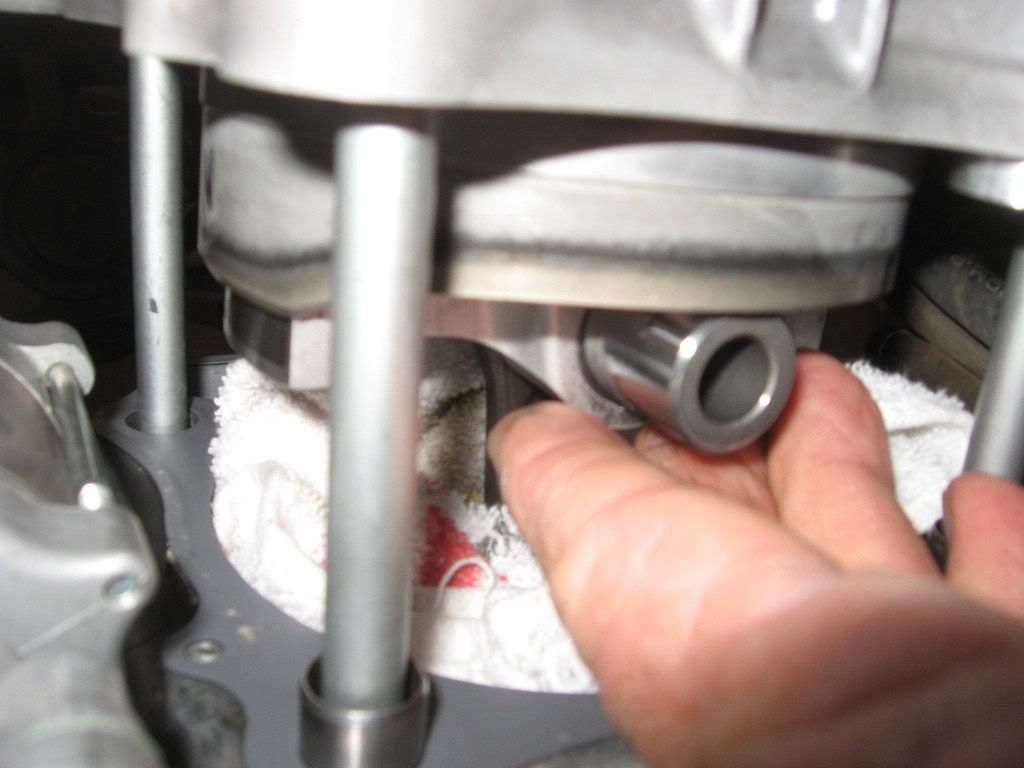

Lube the wristpin journals and pin with oil or oil/MolyLube mixture. Start the pin.

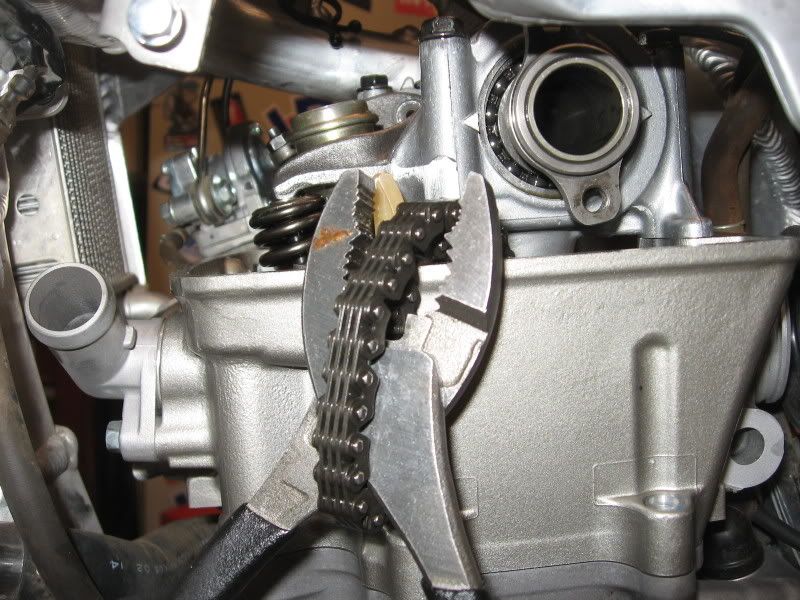

Two wash cloths in the CC hold the ConRod at center, roughly. Start the cylinder down it's path, and feed the camchain up its respective hole, slide the pliers thru the chain.

Batta bing !

Shove one more rag/paper towel in there and drape over exposed stuff. Install the right circlip, gap down.

Lightly blow area and towels, then carefully remove the towels.

Ease that dude on down with a slight rocking motion, and pulling the camchain up. Leave the pliers.

Install left cylinder screw, do not tighten.

And there we have piston/ring replacement.

paul