I recently built a set using the Rad Eagle hub and an Excel rim. Very nice quality.

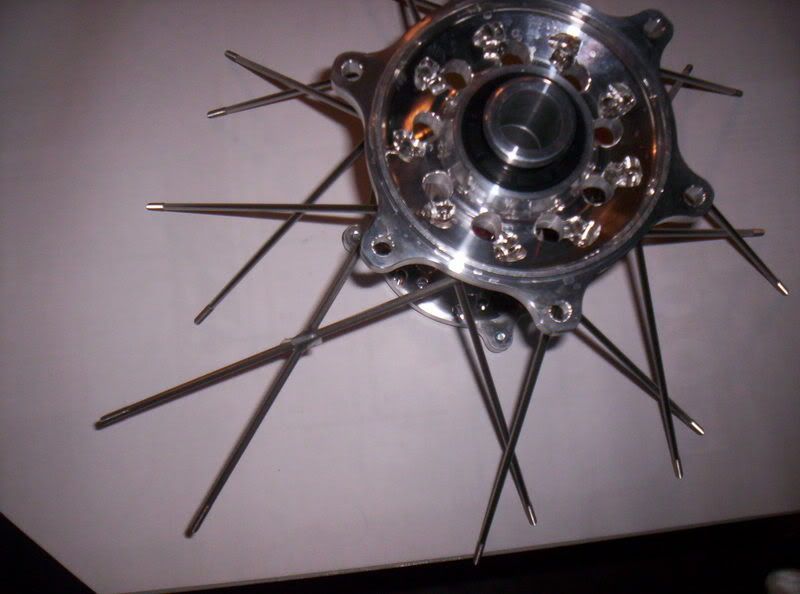

Here's the hub:

Looking at the sprocket side:

The spoke kit was nicely laid out and marked "S" and "D". Sprocket side and disc side.

Some hubs use the same spokes all around,

Rad uses different lengths for each side.

Start by putting the spokes into the chamfered holes in the hub.

The spokes on the outside of the hub should cross over the spokes on the inside of the hub.

Continue until all the sprocket side spokes are in.

Making sure that the outer spoke is crossing over the inner spoke,

put a small wrap of tape about halfway down the spokes at the point of intersection.

Continue until all spokes are done.

Flip over the hub assy to where the disc side is up and start process over.

Continue until all spokes are placed.

Repeat the tape procedure on these spokes as well.

Put the rim over the assembled hub and spokes.

Align rim to match the bevel of the dimples on the rim.

Apply a small amount of AntiSeize to the threaded end of the spoke.

Start threading the nipples around the wheel by hand. They should thread on easily. DO NOT force them.

I use a power driver to snug up all the nipples. Run them down just snug. ( a point at which you could still back them off by hand)

Using a razor knife, remove the tape from the spokes so no one will know you haven't been doing this your whole life.

Next, true the wheel up on the truing stand and Voila, finished.